Unlocking Potential: Lean Six Sigma Green Belt for GBS Success

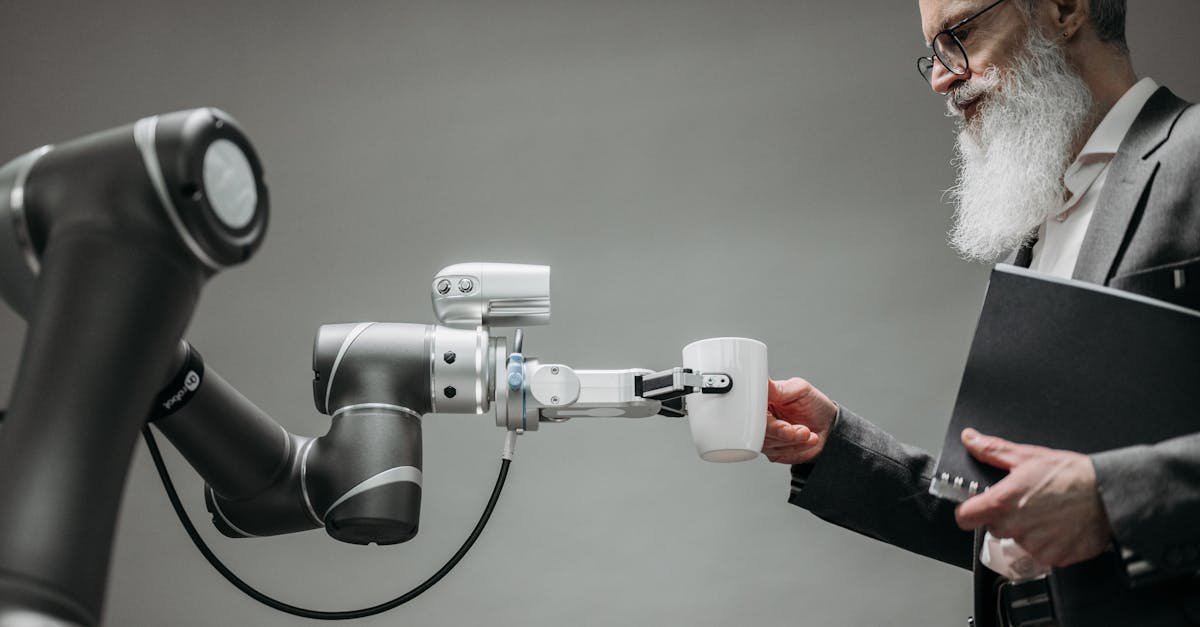

Ever found yourself stuck in a process so tangled that it feels like you’re wrestling with a spaghetti monster? You’re not alone. The nature of shared services often brings layers of complexity that can frustrate even the most seasoned professionals. Understanding how to streamline those processes can feel like a daunting challenge, but what if I told you there’s a proven approach to help you cut through that mess? Let’s talk Lean Six Sigma Green Belt. This isn’t just some buzzword floating around; it’s a powerful methodology designed to enhance efficiency and improve quality. It’s your secret weapon to unlocking potential within your teams and elevating shared services operations to new heights. Trust me, I’ve seen it work wonders in organizations big and small. What is Lean Six Sigma? Lean focuses on streamlining processes by eliminating waste, and Six Sigma targets reducing errors and variability. Together, they create a culture of continuous improvement that can transform the way your team operates. Why Go Green? Becoming a Lean Six Sigma Green Belt isn’t just about getting the certification; it’s about changing the mindset across your shared services landscape. Here’s what you gain: Structured Approach: You gain a robust framework for tackling problems head-on. Data-Driven Decisions: You’ll learn to rely on data to drive process improvements. Collaboration: It fosters teamwork as everyone rallies around common goals. Organizational Efficiency: Streamlined processes translate to quicker turnaround times. Customer Satisfaction: Happy customers often lead to more business. Simple as that! How to Get Started with Lean Six Sigma Green Belt Getting started doesn’t need to be overwhelming. Here’s a simple roadmap: Find the Right Training: Look for accredited programs that align with your business goals. Engage with Your Team: Involve team members in the learning process to foster collective growth. Identify Key Projects: Select a few projects that will benefit most from these techniques. Apply the Concepts: Use DMAIC (Define, Measure, Analyze, Improve, Control) to tackle those projects. Measure & Celebrate Results: Celebrate improvements to reinforce the positive changes. Common Pitfalls and How to Avoid Them When transitioning to Lean Six Sigma, be mindful of these common pitfalls: Neglecting Buy-in: If leadership isn’t onboard, motivation fizzles out fast. Make sure everyone knows the **why**. Overlooking Training: A half-hearted training approach can set everyone up for failure. Invest in quality training for real results. Ignoring Feedback: Your team is the front line. Their input might just lead you to the next breakthrough. Relatable Success Story Let me share a quick story. A colleague of mine in the finance sector struggled with a mountain of year-end reports. The process was slow, error-prone, and downright frustrating. After investing in Lean Six Sigma Green Belt training, they tackled the reporting process using the DMAIC framework. They defined the bottlenecks that cropped up during peak season. They measured timelines, analyzed errors, improved communication amongst team members, and controlled the process to ensure it stayed on track. The outcome? Reporting time was cut in half, errors dropped significantly, and the team felt a renewed sense of purpose! What’s Next for You? If you’re ready to dive into the world of Lean Six Sigma Green Belt, commit to continuous learning and open collaboration. Equip yourself with the right resources and stay aligned with your organization’s strategic vision. And if you’re looking for more insights into shared services transformation and its nuances, I recommend checking out THEGBSEDGE blog. For those curious about process optimization, head on over to our section on Process Excellence to discover more actionable insights. It’s filled with everything you need to know to streamline your learning journey. In Conclusion Lean Six Sigma Green Belt is more than a certification – it’s a mindset that can fuel the success of shared services. By embracing this approach, you’re not just unlocking your potential; you’re elevating your entire team’s ability to meet challenges head-on. So, grab that cup of coffee, rally your colleagues, and let’s start this journey towards process excellence together. There’s a goldmine of opportunity waiting to be tapped, and it all begins with a single step. And remember, if you want to stay in the loop on the latest trends in shared services, subscribe to THEGBSEDGE blog. Let’s unlock our full potential together!

Unlocking Potential: Lean Six Sigma Green Belt for GBS Success Read More »