Designing an Efficient Fulfillment Center for Optimal Performance

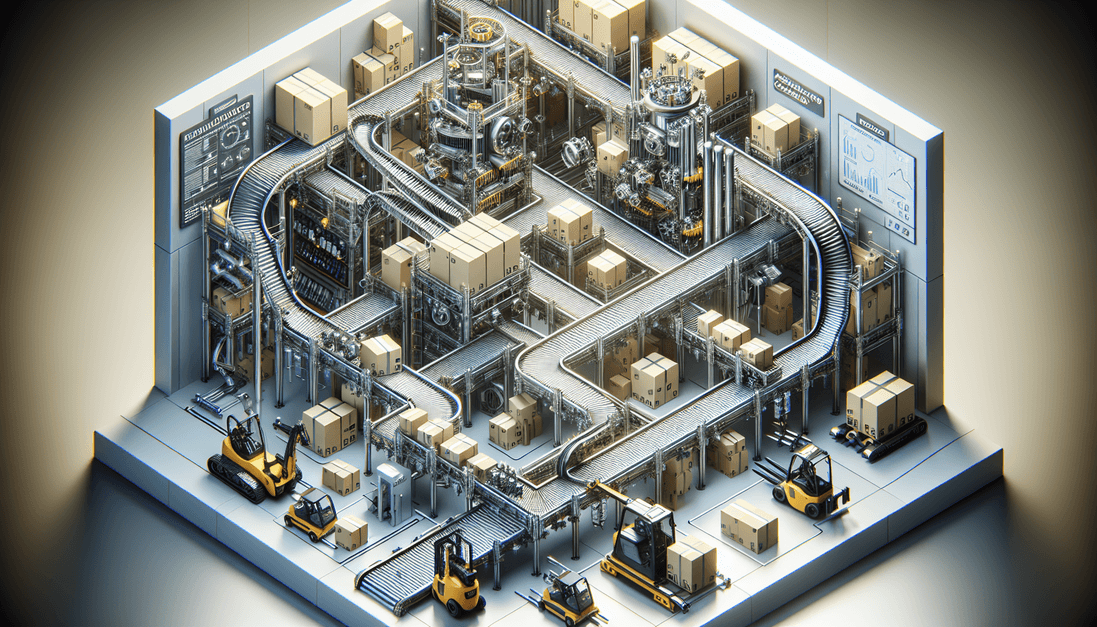

Building a Fulfillment Center that Works for You Ever felt like your fulfillment center just isn’t firing on all cylinders? It’s a common headache. You’re not alone. The right design can turn your fulfillment center into a well-oiled machine. Let’s break this down together: how to design an efficient fulfillment center for optimal performance. Understanding the Basics of An Efficient Fulfillment Center Design A fulfillment center isn’t just a warehouse. It’s a hub of action where products come in, get processed, and head out to customers. To grasp how to optimize this beast, we need to keep a few things in mind: Workflow Efficiency: Every inch of space matters. Technology Integration: Make tech your friend. People and Processes: The heart of your operations. Planning the Space Your fulfillment center needs to be more than functional; it should be smartly laid out. Consider these elements for a killer foundation: Receiving Area: Where products first make their appearance. Storage Space: Think vertical and horizontal for maximum efficiency. Picking Area: The faster your team can pull items, the happier your customers will be. Packing Area: A well-organized space means fewer errors and quicker packing times. Shipping Dock: Streamline this for rapid dispatch. Every phase must flow seamlessly into the next. Workflow Optimization Here’s where it gets interesting. Designing the best layout won’t matter if you don’t optimize workflows. We want to minimize movement and maximize productivity. Here’s a quick cheat sheet: Use the right tools for inventory management. Automate where you can. Think sorting systems or automated packing. Gather feedback from your team regularly. They know the process inside and out. Involve team members who are on the floor. They live it every day. Embracing Technology Let’s talk tech. In today’s world, ignoring technology in your fulfillment center design is a rookie mistake. Your center should be equipped to handle: Inventory Management Systems: Keep tabs on stock levels and automate reordering. Warehouse Management Systems (WMS): Control every aspect, from picking to shipping. Data Analytics: Predict trends and adjust processes accordingly. Being reactive is for amateurs. Let’s be proactive. People Matter Have you ever tried to run a fulfillment center without considering the people in it? Big mistake. Your team is crucial. Empower them. Invest in training, and keep the morale high. Regular check-ins create a sense of community. Celebrate milestones big and small. Listen to their ideas. Some of the best change comes from the ground up. When your team feels valued, they will work harder. Analyzing Key Performance Indicators You can’t improve what you don’t measure, right? Set clear KPIs that matter. Here’s what to track: Order Accuracy: Aim for 99% and above. Fulfillment Speed: Get those orders out the door fast. Inventory Turnover: How quickly are you turning stock? Don’t just hit numbers; analyze them for insights. Creating a Culture of Continuous Improvement Design isn’t a one-and-done deal. It’s about evolving. How can you keep the momentum going? Hold regular training sessions. Review processes often. Are there chances to streamline? Encourage teams to share success stories and challenges. When improvement becomes part of your culture, you’ll see amazing results. Case Study: A Real-world Example Let’s talk about a client I worked with. They were facing a mountain of issues in their fulfillment center. Orders were delayed, and customer complaints were skyrocketing. After analyzing their space and systems, we made strategic changes: Implemented a new WMS. Redesigned the picking and packing areas. Trained staff on new technologies. Within months, their efficiency improved drastically, and order accuracy skyrocketed to 98%. Conclusion: Building Your Fulfillment Center for Success Designing an efficient fulfillment center is no small feat. But when you focus on workflow, technology, and your team, the results can be phenomenal. Remember, it’s all about optimizing for the best performance. Your fulfillment center can be a powerhouse, propelling your sales and delighting customers. So, let’s get to work on making it happen!

Designing an Efficient Fulfillment Center for Optimal Performance Read More »